Advance Fittings offers a broad range of Biopharmaceutical fittings for process component applications. Important features are proven to fulfill the exacting installation and operational requirements.

Our fittings are essential components in the biopharmaceutical industry. Their key functions include:

- Maintaining Sterility: Biopharmaceuticals are often delicate and require a completely sterile environment to prevent contamination. Our BPE fittings are designed with smooth surfaces and minimal crevices to minimize the risk of bacteria or other microorganisms harboring. Additionally, the high-grade stainless steel materials can be easily cleaned and sanitized.

- Ensuring Product Integrity: Leakage or contamination from faulty fittings can ruin an entire batch of biopharmaceuticals. BPE fittings are designed for secure connections and can withstand high pressures and temperatures commonly used in processing. This minimizes the risk of leaks and ensures the product remains pure and potent.

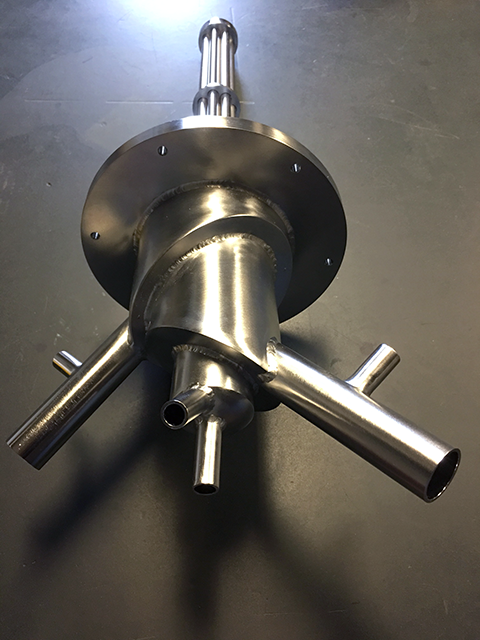

- Facilitating Efficient Flow: Biopharmaceutical processing often involves transferring large volumes of liquids, gases, and cell cultures. Our BPE fittings are designed with optimized flow paths to minimize resistance and maximize efficiency. Secure sealing mechanisms like clamps, flanges, and gaskets help ensure consistent production quality and reduce downtime.

- Flexibility and Scalability: Advanced Fittings’ products are available in a wide assortment of shapes, sizes, and configurations. This allows you to design and assemble processing systems that meet your specific needs. You can also easily scale production up or down to meet fluctuating demands.

For over 30 years, Advance Fittings has devoted its energies to producing the highest quality fittings for use in the biopharmaceutical industry. We consistently surpass the requirements needed in this industry to assure each fitting will perform with integrity when installed into the processing system. Contact us today to learn more!