Did you know that the word “laser” is an acronym? It stands for light amplification by stimulated emission of radiation. Laser Marking uses a beam of light to slightly alter the surface of a material. The beam can target a specific area which creates high quality marks that are easy to read. These marks often consist of letters, numbers, logos, pictures, and signs. They are placed on surfaces such as metals, wood, leather, fabric, plastic, and glass.

There are four common types of laser marking: annealing, carbon migration, foaming, and coloring. Annealing is used to mark materials that contain carbon, such as steel, iron, titanium, and stainless steel. Carbon migration involves the formation of a chemical bond between the metal and carbon molecules, a much faster process than annealing. Foaming is used solely on plastic material. Finally, coloring is used on both plastics and metal, and can produce a wider range of colors.

There are many advantages to using laser marking; the marks made with this process are clean, permanent, and will not disintegrate over time, the marks cannot be altered easily (minimizes counterfeit products), no internal stress will be placed on the piece being marked, it can be used on several metal and non-metal materials, very precise and high-definition markings are made, lower operational costs, quick turnaround time, the printing designs are able to be changed out quickly and easily, and the process is affordable.

Who uses laser marking? The automotive industry uses laser marking to place a vehicle identification number on each vehicle being produced. Manufacturers use laser marking to apply bar codes, QR codes, serial numbers, and part numbers to products. The pharmaceutical industry uses laser marking to mark pills quickly and easily. Stainless steel surgical equipment is marked using laser marking for the medical industry. Just about any industry can benefit from using laser marking on their products to add logos, serial numbers, etc. If you have ever bought a leather wallet or purse with an embossed logo on it then you have also benefited from laser marking.

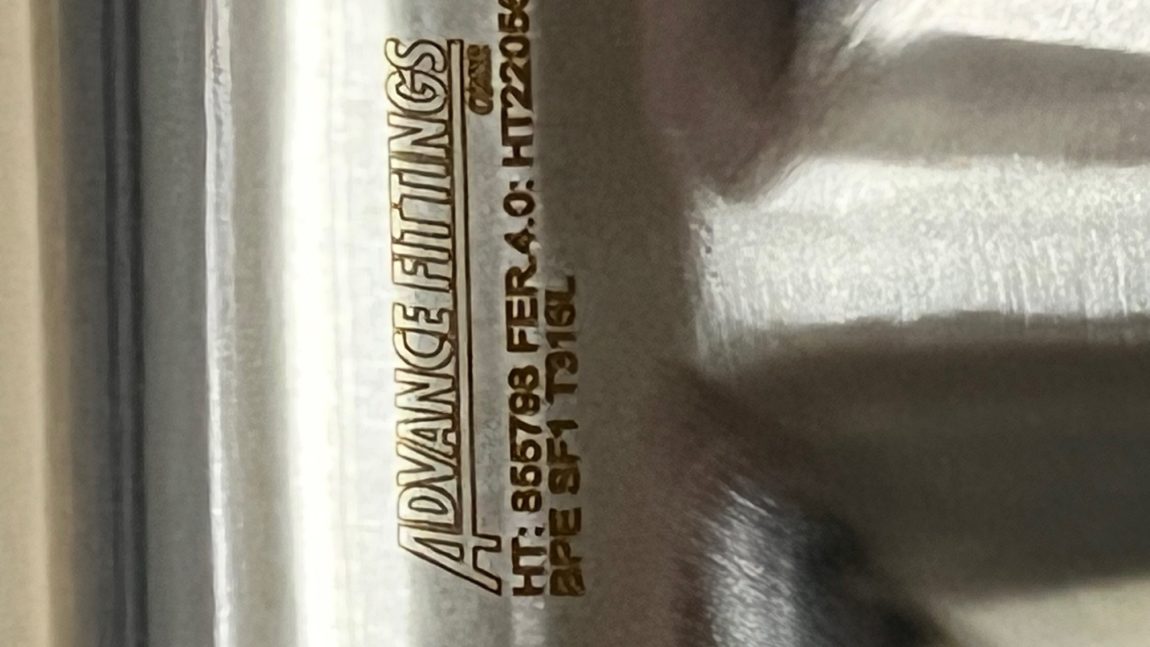

Contact Advance Fittings today for your laser marking needs!

Leave a Comment